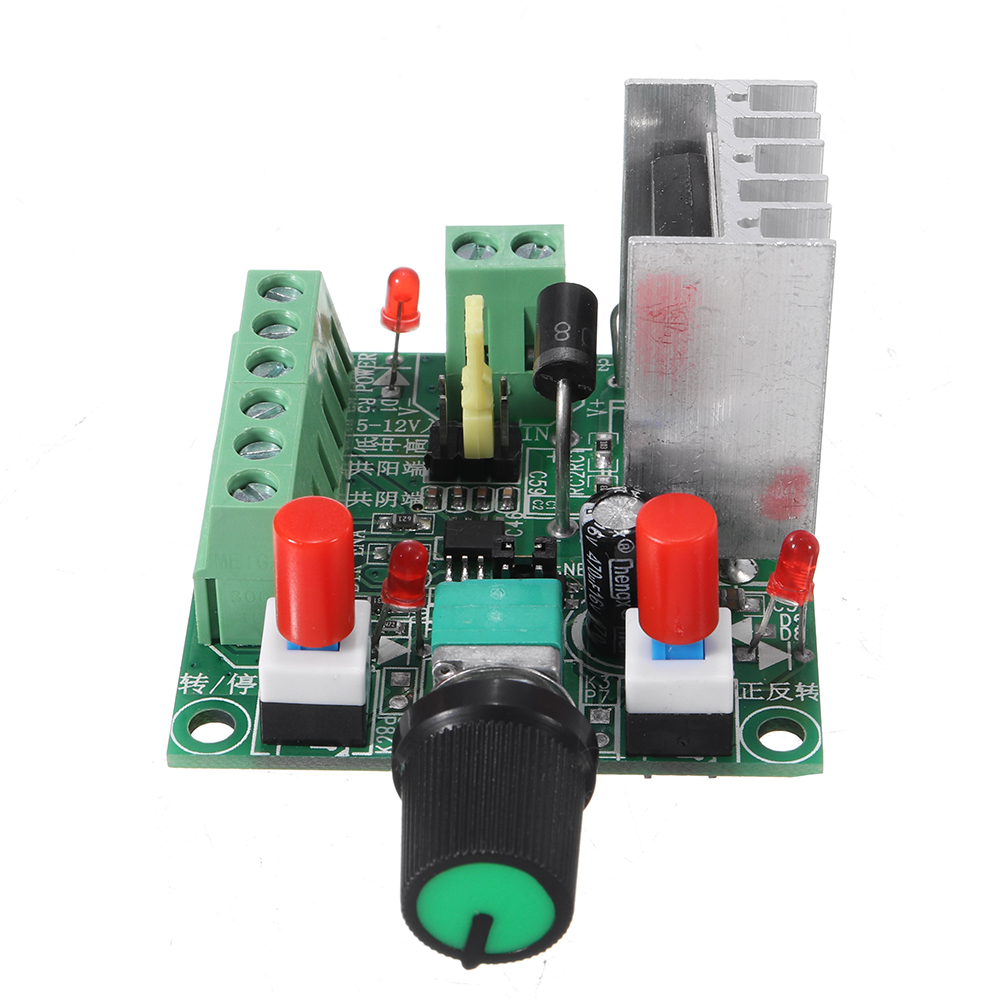

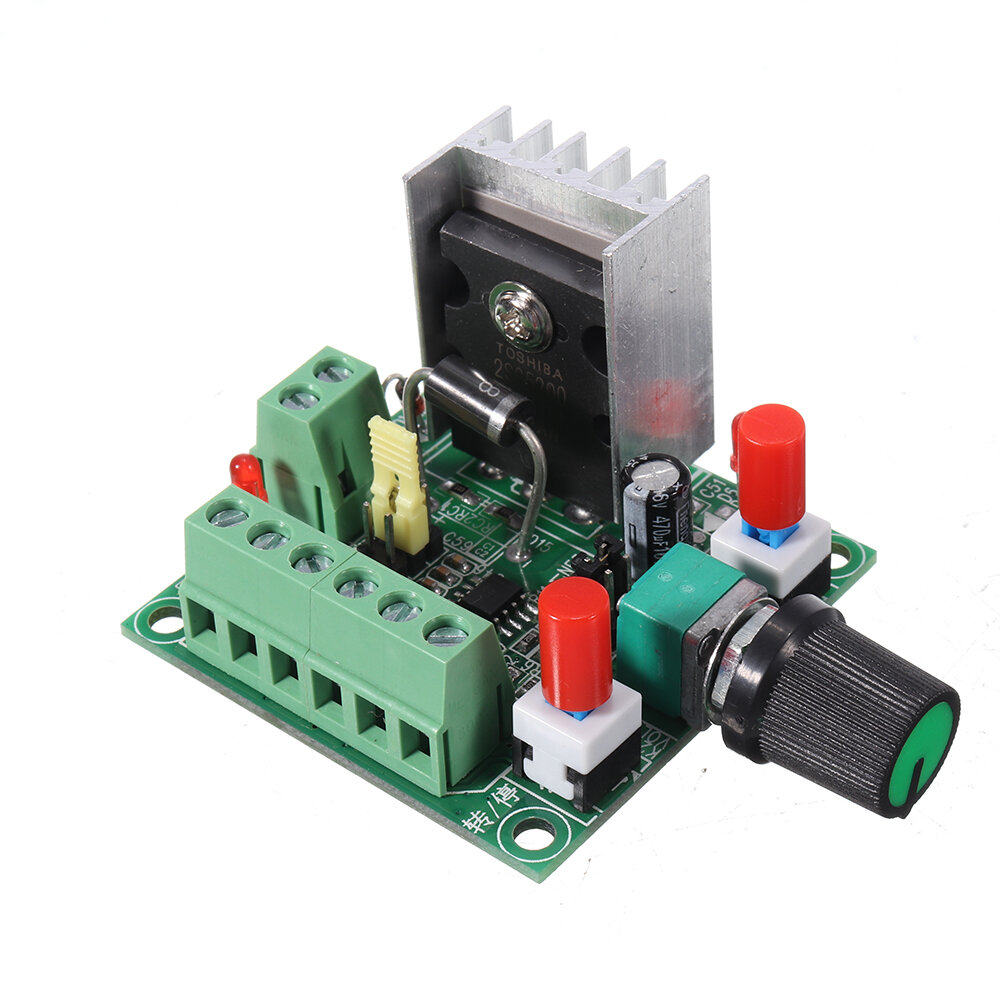

PWM Stepper Motor Driver Simple Controller Speed Controller Forward and Reverse Control Pulse Generation

Feature:

Product name: simple controller

Product name: simple controller

Model: CW-S01

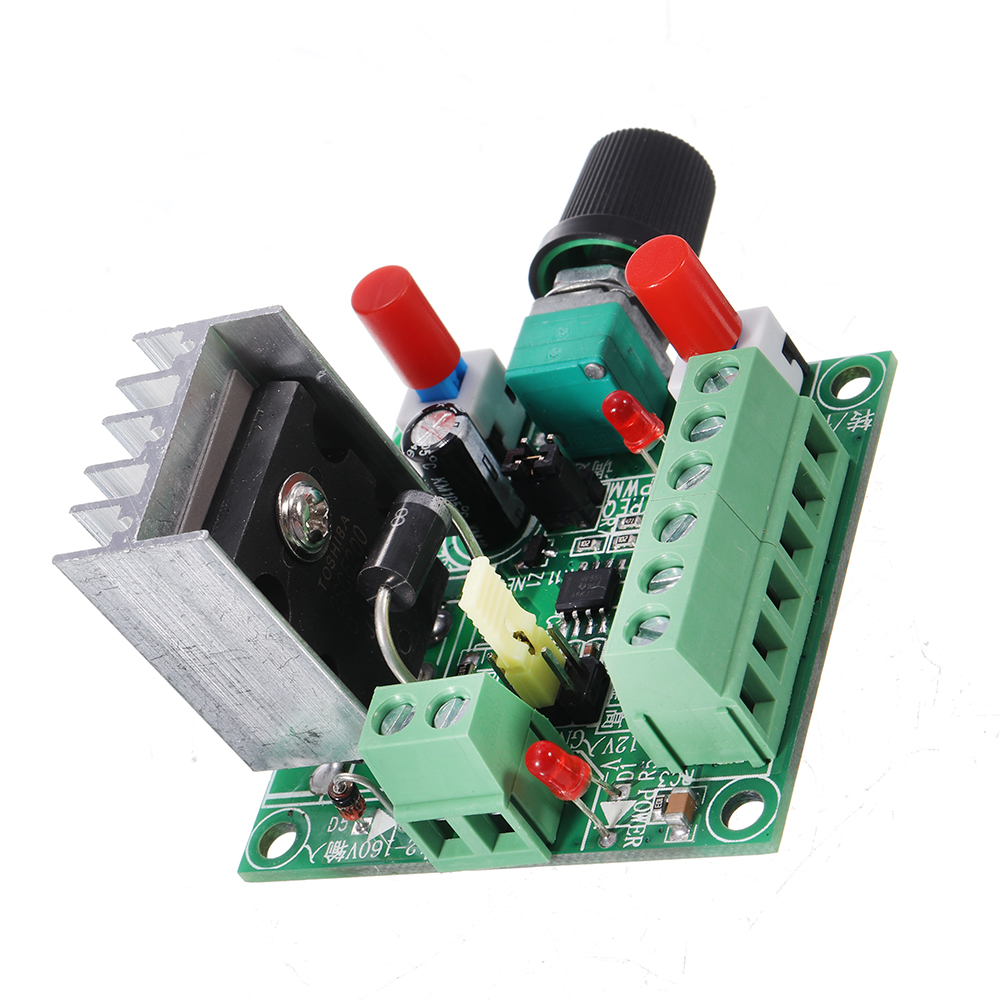

It can generate PWM signal. There is a jumper on the board, which can be set and selected. By default, it is set to generate pulse frequency signal.

Product Manual:

1. When the controller generates a pulse frequency signal, it can supply a stepper driver as a signal. To control the stepper motor, it must be equipped with a driver.

(This simple controller + stepper driver + stepper motor + DC power supply can form a simple control platform.)

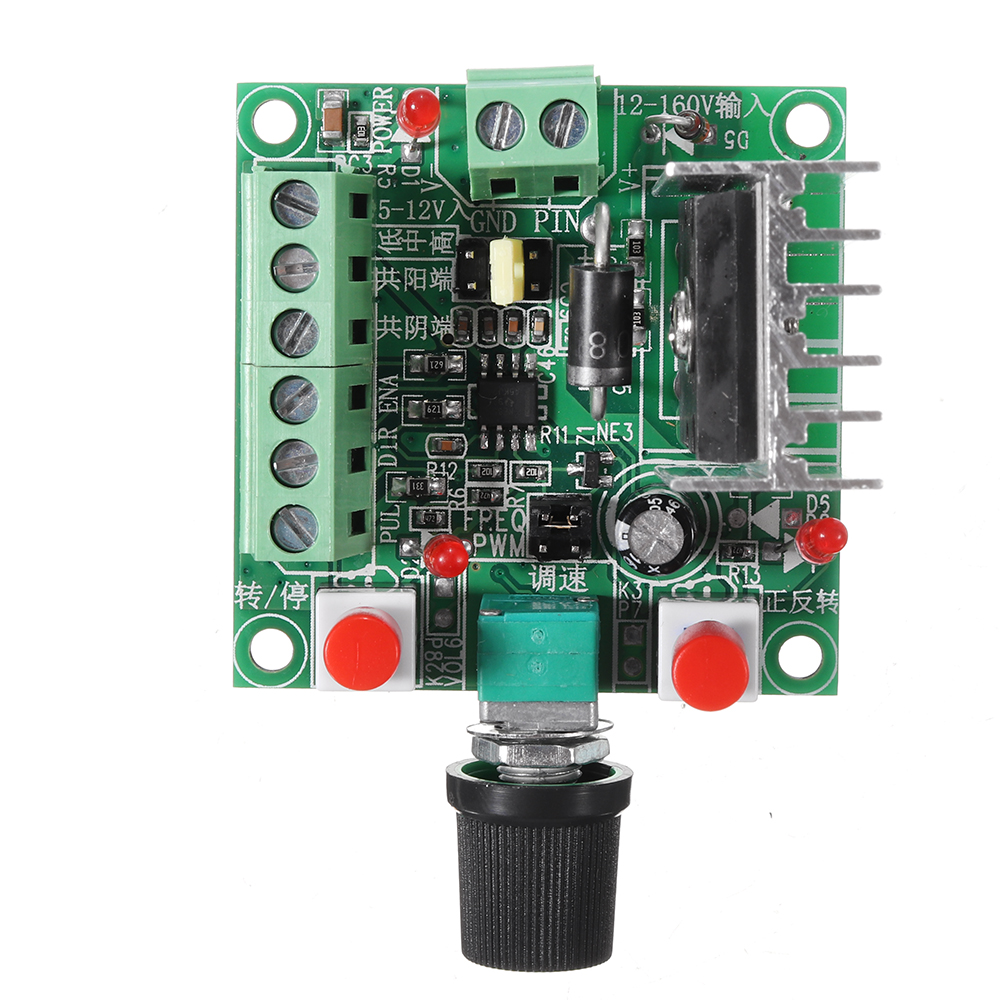

2. The controller can generate a pulse frequency signal or a PWM pulse width signal. There is a jumper on the board, which can be set and selected. By default, they are set to generate pulse frequency signals.

REQ is to generate pulse frequency signal

PWM is to generate PWM signal

3. When the controller generates a pulse frequency signal, there are three types of high, medium and low frequency signals that can be selected with a jumper. The frequency parameters are approximately:

High: 5.8KHZ-127KHZ

Middle: 590HZ-15.8KHZ

Low: 82HZ-2.3KHZ,

Frequency measurement: You can measure PUL and common cathode (GND) two ports.

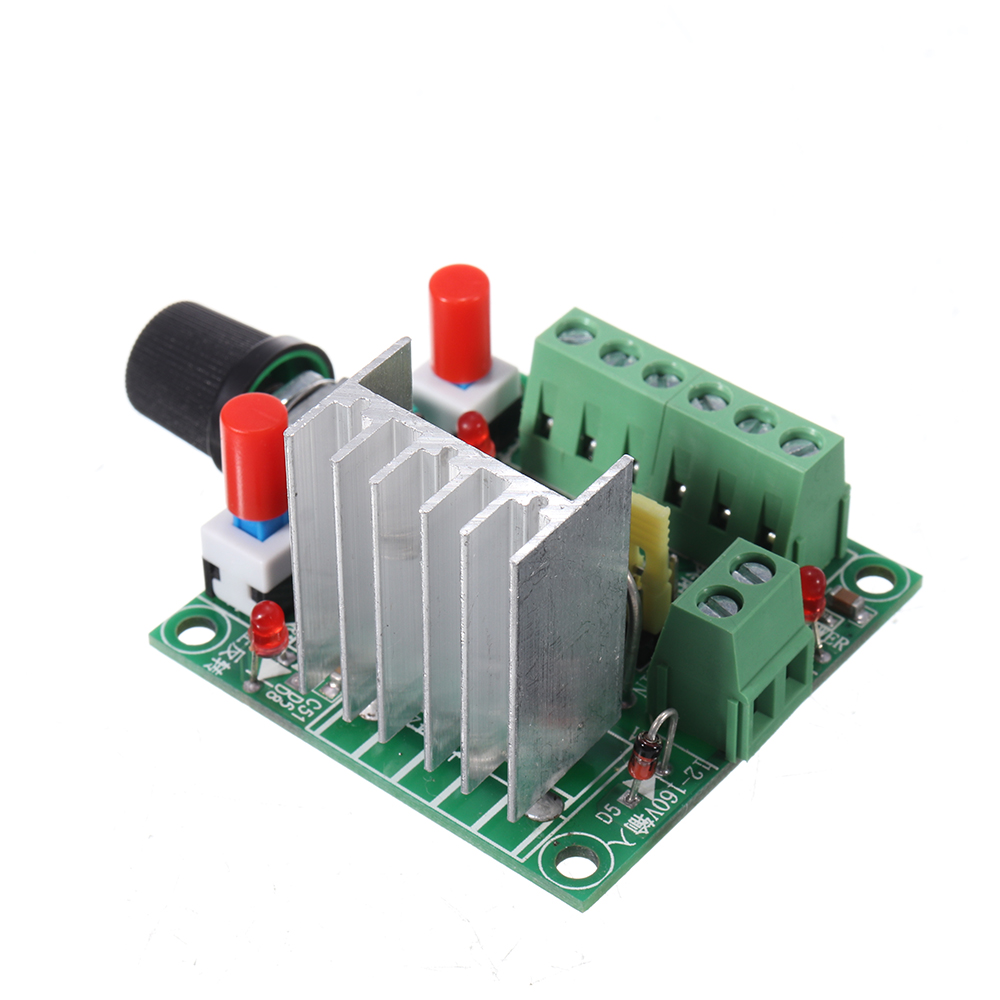

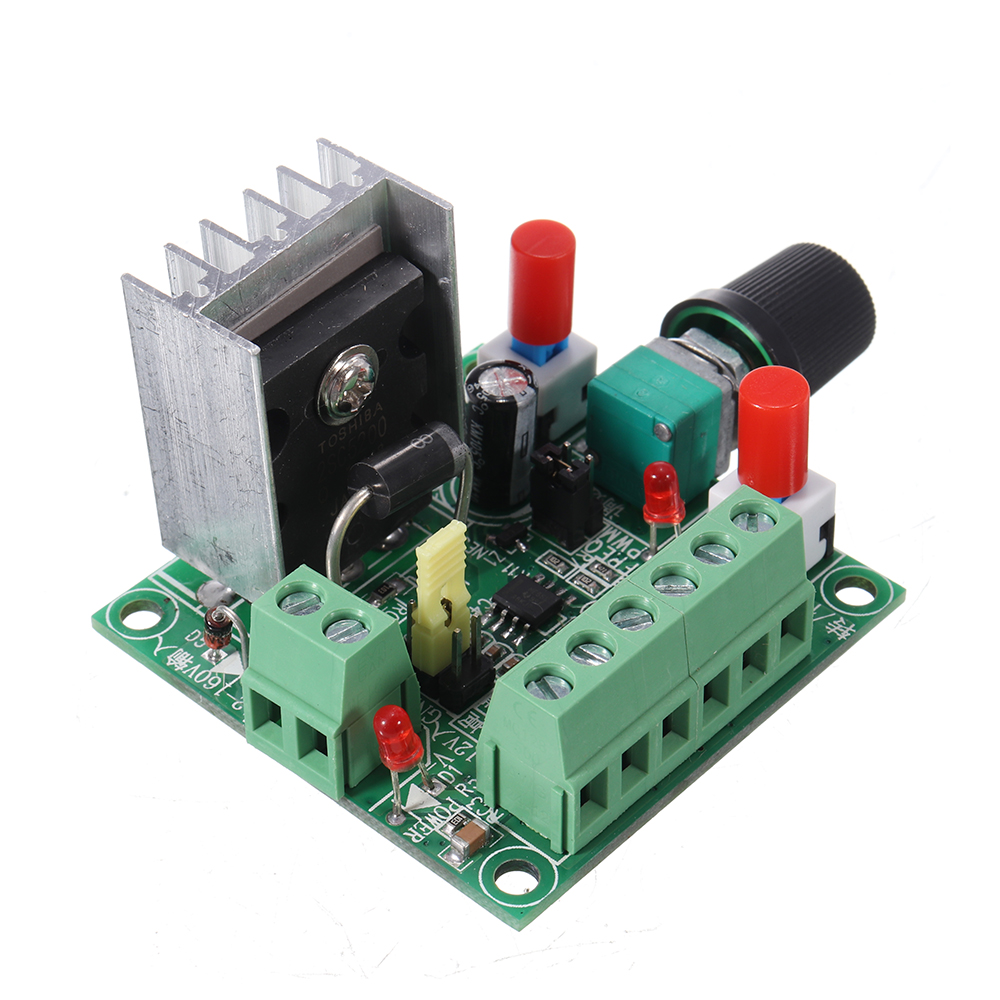

4. The power supply has 2 sets of power input, and 2 sets only need to connect one set of power supply. It is recommended to use a power supply of more than 15V. Connect to the power supply of the 2-bit terminal, do not connect the positive and negative.

One group is the power supply connected to DC 15-160VDC, and the recommended operating voltage is 15-80VDC.

The other group is 5-12VDC. When used with the driver, it is recommended to use a minimum of 12V, not a 5V power supply, not at 5V, the power supply is connected to "5-12V input", and the power supply is connected to the "common cathode".

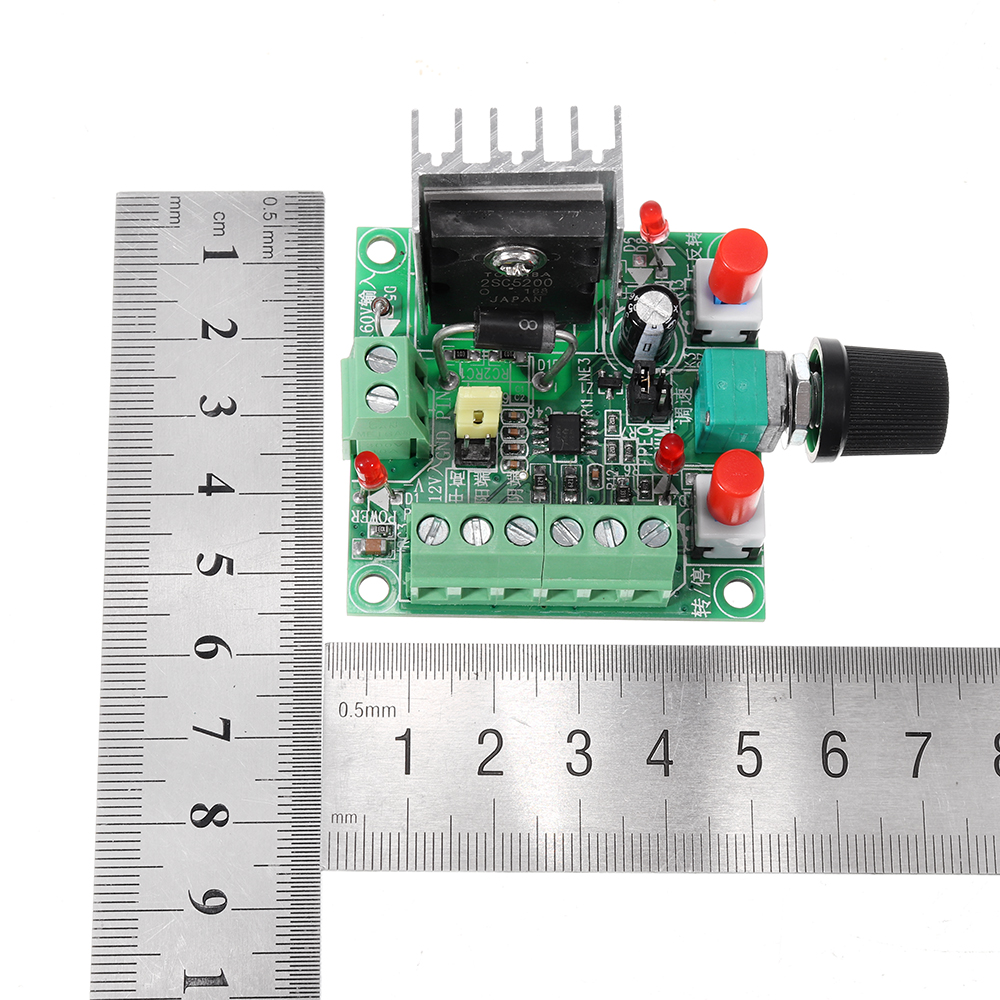

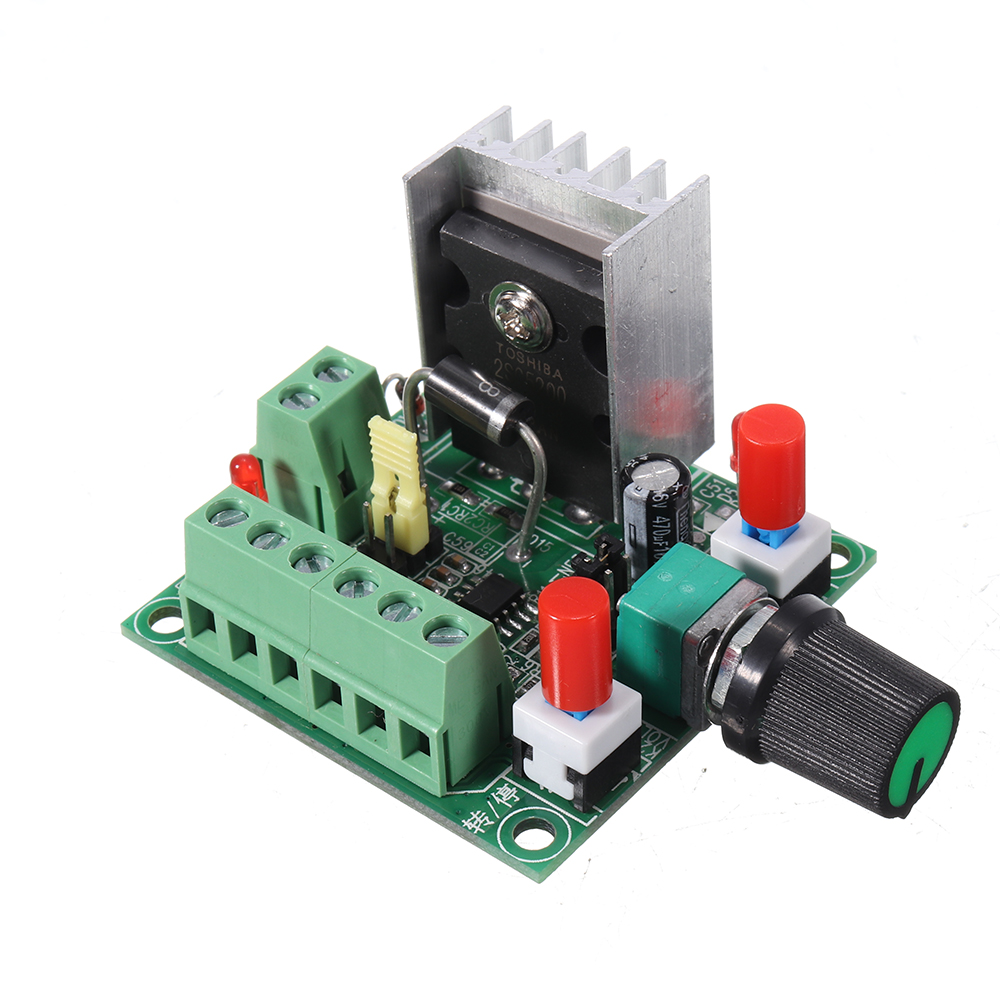

5. Length * width * height: about 73 * 51 * 37MM

Example: Wiring with the common anode of the driver. If it is driven by 6 signal lines, the + 5V common terminals of the three signals must be connected in parallel to form a line and all connected to the common anode terminal.

Package includes:

1 x Controller

Note:

Controller | Driver |

PUL | Pulse negative terminal (PUL-) |

DIR | Negative direction (DIR-) |

ENA | Enable negative terminal (EN-) |

Common anode | Common port (COM or + 5V or PUL + DIR + EN + are connected at the same time) |

Common cathode | Common ground (GND) |

5-12V input+ | The positive end of the 12V power supply is generally empty.It is recommended to use a power supply of more than 15V. |

Example: Wiring with the common anode of the driver. If it is driven by 6 signal lines, the + 5V common terminals of the three signals must be connected in parallel to form a line and all connected to the common anode terminal.

Package includes:

1 x Controller

Note:

1. If you want to use the start or stop function, the ENA enable terminal on the controller must be connected to the driver with a common cathode or a common anode.

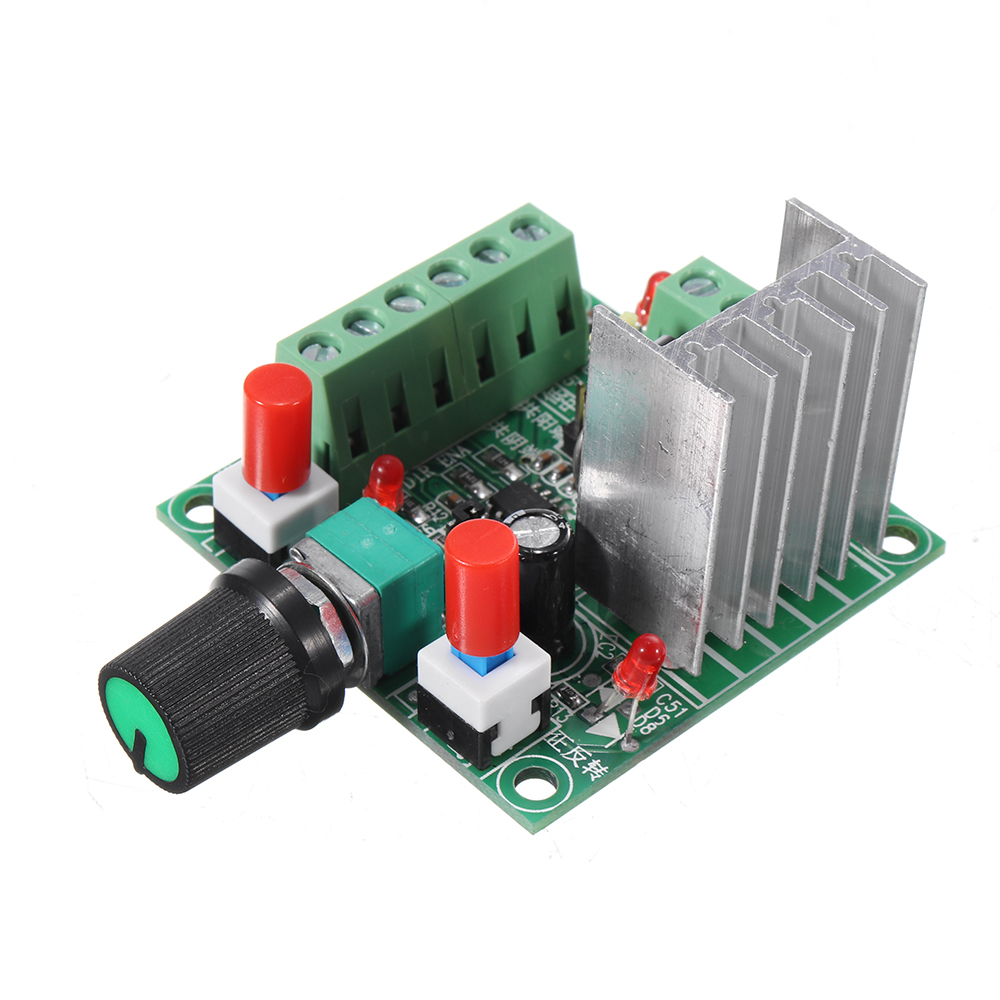

2. The forward and reverse rotation and the start and stop of the motor can be controlled by pressing the button.

3. The speed of the motor can be controlled by adjusting the potentiometer to change the frequency.

4. The switch of the motor's forward / reverse rotation and start / stop is an ordinary switch with self-locking.

5. If you want to connect the switches that control forward and reverse, and open or stop, to the chassis panel, you can refer to the following instructions.

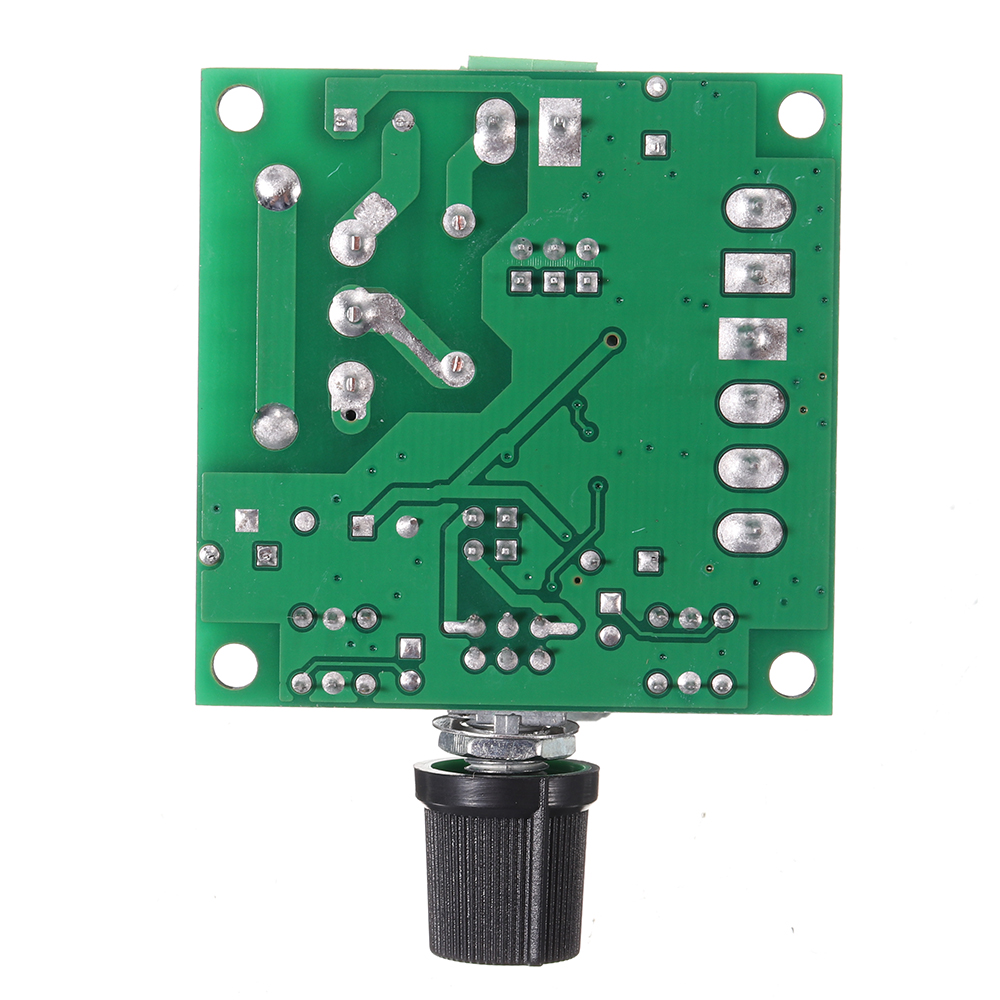

Change the forward and reverse, the start-stop button into a lead-wire switch, see the pin position on the back:

1. When the common cathode is connected, the 1 and 3 pins are processed, and the 2, 4, 5, and 6 pins are empty

2. When the common anode is connected, the 1 and 2 pins are processed, and the 3, 4, 5, and 6 pins are empty

The two switches are the same pin lead.

PWM Stepper Motor Driver Simple Controller Speed Controller Forward and Reverse Control Pulse GenerationSee detail